AR-15 Gas Systems Guide

Gas. It can cause blinding flashes, especially when firing your AR-15 with a muzzle brake. It is also a crucial element to how your AR-15 rifle functions. To avoid any critical mistakes with your 80% build, read on below!

Before we dive in any further, here’s what you’ll learn here today:

- The most common types of AR-15 gas systems.

- How an AR-15 gas system works.

- Key components within the AR-15 gas system.

- Why AR-15 gas system lengths matter.

- The best adjustable gas blocks on the market today.

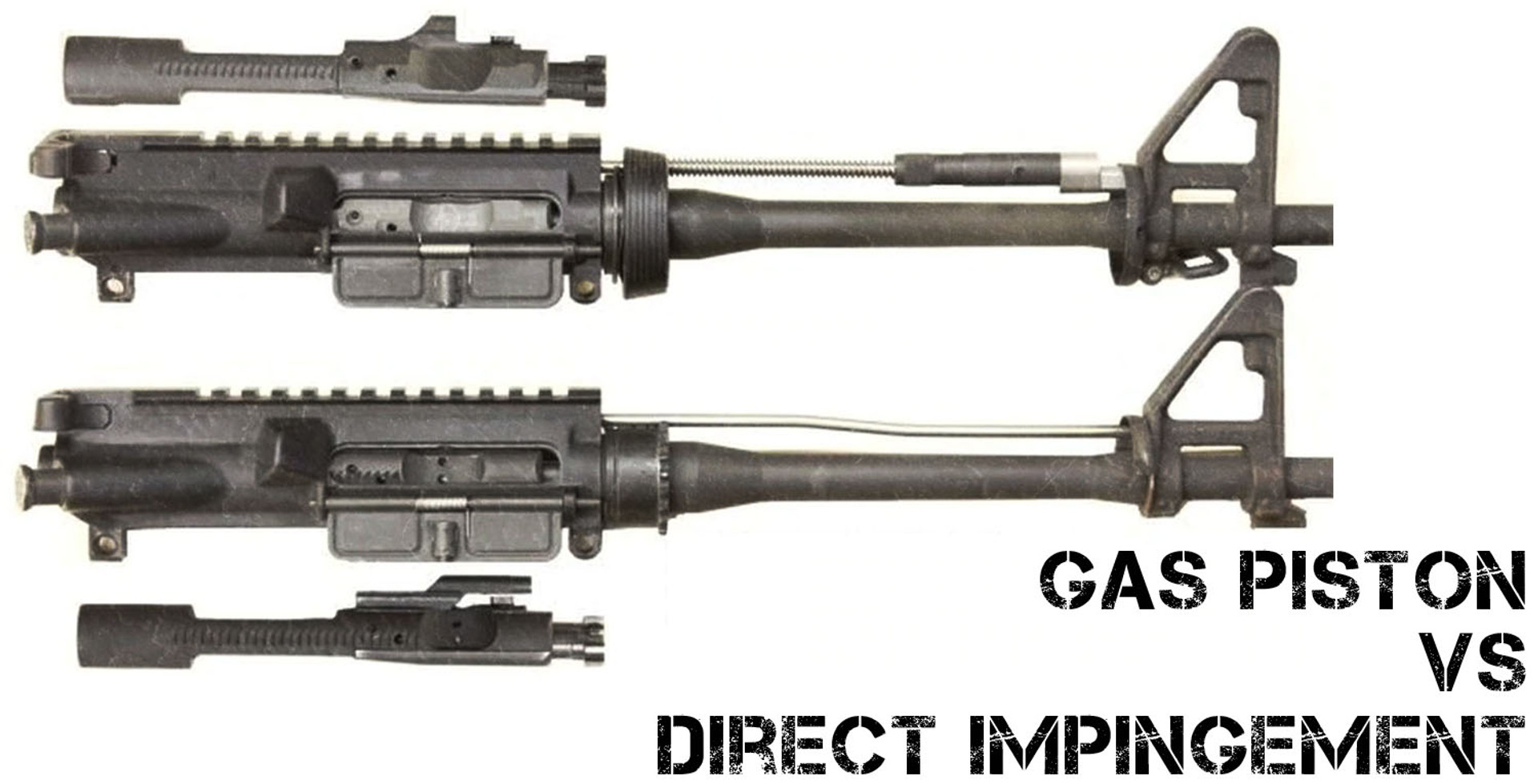

Two Types of AR-15 Gas Systems

Gas-recoil systems were designed to replace rifles’ need for a manual bolt – allowing for a much higher firing rate. For the AR-15, there are two types of gas systems to know: direct impingement and piston systems.

Photo Credit: Silencer Central

What is Direct Impingement?

Direct impingement redirects gas from a fired bullet to push out the empty casing and load the next bullet.

Direct impingement in AR-15: how it works

AR-15 direct impingement gas system utilizes a hole on the top of the barrel which is called the gas port. The gas block covers this hole to redirect the gas thru a tube which goes on directly to the gas key of a bolt carrier group.

Depending on the length of your AR15 barrel the distance from the BCG's gas key to the gas port will vary. The varying distances from the gas key to the gas port is as follows:

- On a pistol-length gas system: 4” apart

- On a carbine length gas system: 7” apart

- On a mid-length gas system: 9” apart

- On a rifle-length gas system: 12” apart

In other words, these lengths above would be how long of a gas tube you’ll need.

Ideally, the strong gas pressure pushes the bolt carrier backward to remove the spent casing and smoothly load the next round as the bolt moves forward.

When attempting to improve and adjust the performance of your AR15 to reduce the kickback you feel or control the muzzle flip, the interaction between the gas flow and the choice of buffer weight or spring becomes crucial.

Pros and Cons of Direct Impingement

Some claim that the high-pressure gas also helps to blow debris such as mud away from the bolt head should the case ever arise. However, if small debris and objects have gotten that far into the action, it’s probably best to do a proper field strip and cleaning to save yourself the trouble of malfunctions and extraction problems.

The hot gas exerted from the burnt propellant contains gaseous forms of carbon and impurities. As the gas cools down and coats the insides of your upper receiver, the particles condense and turn into a graphite-like layer on the surface of the bolt and receiver.

This fouling, or carbon build-up, occurs much more frequently and inevitably with a direct gas impingement system.

As Eugene Stoner used cleaner burning powder during the AR15 development, soldiers found themselves facing fouling-related malfunctions early in the M16’s introduction due to the Army’s dirtier burning ball powder and the absence of standard-issued cleaning kits. The M16 was equipped with 20" barrels.

Today, most AR15 owners use 16" barrels and even shorter ones. Shorter barrel lengths provide greater maneuverability especially when mounting muzzle devices like suppressors.

There's an increasing expectation among gun owners that there’s a possibility they’ll have to move around in suburban environments as well as enter and exit vehicles. The downside to using a direct gas impingement system on a short barrel is the sharp increase in gas port erosion.

What causes the harsher wear on the barrel's gas port?

The shorter the distance of the gas port to the gas key, the more pressure the gas port is subjected to. As the gas port widens over time, more gas will be introduced to the system and can overgas your action. However, this can also be fixed with an adjustable gas block tuning.

Advantages

- Lightweight gas system

- More widely available

- Inexpensive

- Easy to produce

Disadvantages

- Requires more frequent cleaning and lubrication

- Hot gaseous carbon and burnt propellant particles can be directed toward your face

- Gas ports erode over time. Shortening the gas system increases the erosion rate.

Piston System

The piston system is an alternative gas system for the AR-15. Originally designed by Mikhail Kalashnikov for the AK-47, there are a lot of similarities between the direct impingement and piston system in that they both use redirected gas to push the bolt carrier back for case extraction and semi-automatic fire functionality. The key difference is that for the piston system, redirected gas is contained in a separate cylinder which actuates a piston that pushes a one-piece bolt and rod backwards which is connected to the BCG.

Still not clear? Check out these great visual aids to see how the two gas systems work:

What is a Gas Piston in AR-15

In a piston-driven AR gas system, intermediary rods are used to transfer the force of high-pressure gas from the gas block to the bolt carrier group, allowing the action to cycle.

Gas piston in AR-15: how it works

The piston-driven gas system uses similar gas block principles to the direct gas impingement system. Rather than having a gas block sized for a gas tube, it accommodates a rod that is pressed up against a second tensioned rod which leads to the gas key.

As the gas exerted by the burning propellant reaches the gas block, the first rod is thrown against the spring-tensioned rod, launching the secondary rod into the bolt carrier. This pushes the bolt carrier group back to extract the spent cartridge and proceed with cycling. The spring resets the secondary rod and sends the two rods back into the ready position.

Pros and Cons of Gas Piston

Gas piston ARs are on the pricier side as they are all entirely proprietary designs and are therefore more expensive for companies to produce. That being said, a quality gas piston AR can be worth every penny. A piston-driven system introduces zero burnt propellant gas into the upper receiver. This clean-running gas system holds an edge over direct impingement in terms of reliability.

Without being sprayed repeatedly with hot high-pressure gas, the action doesn’t heat up or dry out as quickly as direct impingement cycling either. This puts less wear on the firearm and really helps things keep running in rapid fire.

The rods for a gas piston system are a bit heavy, hence why piston-driven uppers and rifles, in general, are the heavier flavor of AR15s.

Advantages

- Cleaner, smooth cycling operation

- No gas directed toward your face

- Doesn’t need to be lubricated as often as direct impingement

- More reliable

Disadvantages

- Slightly heavier

- Noticeably harder recoil

- Usually more expensive and uses proprietary parts

Gas Piston vs Direct Impingement Comparison

Direct impingement ARs are standard in the AR15 market. But there are also great options for gas piston kits for an AR build. There are reputable AR brands of both gas system types that perform exceptionally. Daniel Defense, Knights Armament Company, and many other high-end manufacturers produce flagship AR15s such as the DDM4v7 and SR15 using direct impingement gas systems.

Great piston ARs include the HK416/MR556A1, MARS-L 556 Piston, IC-SPR, and much more. Piston-driven ARs and other short-stroke gas piston platforms like the FN SCAR17 and Steyr AUG have proven their consistent quality in harsh, abusive environments and can keep chugging for long durations without maintenance. You do still need to clean and lubricate gas piston firearms. Rather a lubricated and cleaned short-stroke piston rifle will perform more reliably than a lubricated and cleaned direct impingement.

A gas piston-driven AR adds additional moving parts to the firearm's cycling action. While not a significant factor when buying from manufacturers that have a reputation of good tolerance to uphold, this should be taken into consideration if you're looking for precision match-grade rifle characteristics rather than longevity. A direct impingement rifle, while sending gas toward your eyes and nose, does shoot softer and more accurately.

Piston-driven ARs have been designed since 1963. Eugene Stoner did develop the Armalite AR16, a 7.62x51mm short-stroke gas piston rifle resembling similar to the AR10. Just like its direct impingement counterpart the AR16 was scaled down to use 5.56x46mm.

This resulting mini-AR16 rifle is known as the AR18. By the time production began, the AR-15 was beginning widespread adoption within the US armed forces and overshadowed the improved piston-driven AR18.

Which System is Right For You?

While the focus of this article is on a comparison between gas piston systems and direct impingement, gas systems alone should not be the primary feature to decide the firearm for you. A gas piston firearm that's poorly designed or manufactured with loose tolerances will surely be outperformed by a direct impingement firearm made with quality parts.

If you’re looking to get started on building out your own lower, our 80 lowers will fit any mil-spec tolerance upper receiver no matter the gas system. Fancy trying them out? Pick up an 80 lower jig and get to milling!