Mounting Pistol Red Dot Sights

With the exception of some revolvers, red dots for handguns typically aren’t mounted via Picatinny rails. Pistol red dots have brand-specific mounting patterns so whether you're using a strike or hammer-fired pistol it's important to make sure you have an optic with a compatible footprint that will fit your slide.

The next question is if your pistol slide can accept optics at all. But if it can, is it cut for the correct footprint that you need? We'll talk about how to get around this issue in a couple different ways.

What is an optic footprint?

A footprint in the context of red dot sights is the sight’s specific mounting pattern. Typically this refers to the layout of where the red dot sight’s threaded holes are on the underside, but some sights like the Aimpoint ACRO use a wedge threaded into the bottom of the adjacent side of the housing to tension against the slide.

Here are the two most common ways of achieving a matching footprint:

Slide Cuts

Photo Credit: Alpha Shooting Sports

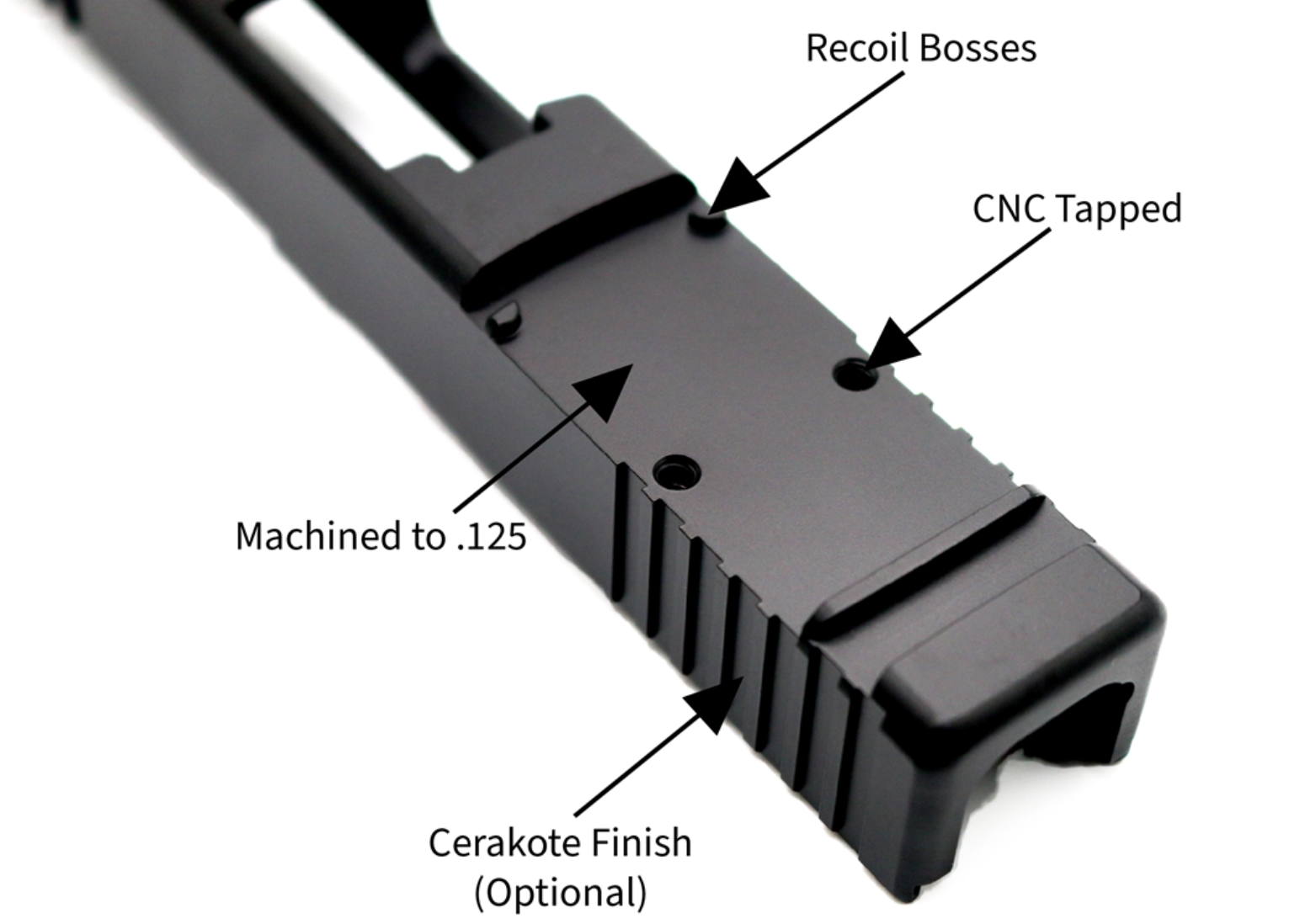

Slide milling is associated with CNCing serrations and windows on a pistol slide for better traction in racking as well as removing weight for faster cycling. The top transverse surface of the slide can have a section cut out, usually in front of the rear iron sights, to match the footprint of a red dot sight.

This is a permanent slide modification but as an aftermarket service, it is the most straightforward means to getting any red dot footprint you want that could possibly fit on your slide. A slide mill ensures the tightest tolerance fit between your red dot sight and your pistol slide. It's simply cutting or drilling the surface to mate.

Adapter Plates

Photo Credit: Primary Arms

Many pistol slides come with a generic optic-ready footprint already milled into the slide. But what if you want to run something that isn’t your average flavor of an RMR or 407C? Sending in your slide to be milled is always an option but another option is to mount an adapter plate over the footprint that has already been factory milled to match the desired footprint.

If your pistol slide doesn’t have a factory sight footprint milled whatsoever, odds are that they will have a dovetail-shaped cut for the rear iron sights — and those can be used for mounting adapter plates as well. For handguns on the thinner side such as the P365 family, plates may be necessary to mount non-compact pistol sights. The width isn't wide enough to accommodate even an RMR footprint.

While ordering and installing an adapter plate is logistically easier than hiring a shop to do a custom slide mill, the extra height from an adapter plate can make it harder on the eyes to acquire the dot as well as the transition from red dots to iron sights. Although some shooters report the contrary and enjoy the additional height over bore. Nevertheless, users have to understand that an adapter plate is introducing a variable to a crucial part of the firearm operation that will eventually fail.

Pay attention to torque spec

Torque spec is respective to each red dot model and should be found on the manufacturer's website. Going over the recommended torque can risk stripping the screws. Many individuals go with a “one-finger” method: hold the Allen key’s short side down with the index finger while seated against the screw, and torque it using just your thumb until it’ll go no further.

Blue Loctite usually comes pre-applied to the screws packaged with the red dot, but apply and cure as necessary to ensure the hardware points stay put. To keep track of the screws staying where they should, you can use a sharpie to draw a dot/line where the edge of the screw touches the surrounding space. If the screw loosens, you’ll see that the mark you made is not in its original shape much easier.

Backup Pistol Red Dots on Rifles

Photo Credit: Badass Optic

Low-powered variable optics have made significant gains over the past decades. The principle of an LPVO is a package that can positively identify targets out to over 200 meters away but still be able to have use in close quarters. Eotech VUDU, Vortex Razor HD Gen III, and NightForce ATACR are all hot commodities in current demand.

It is, however, a compromise. Close-range target acquisition will always be faster on a red dot than on a scope. So why not slap one next to your primary optic or on top of it?

Adjusting an LPVO to 1x magnification takes more time than simply tilting your firearm or looking above the optic to switch to a red dot sight mounted in conjunction with the scope. Here are the two popular mounts for backup red dot sights.

Canted picatinny mounts

Photo Credit: Optics Planet

Using the Picatinny space where the rear backup iron sights typically go, a canted mount puts a red dot sight right next to the eyepiece of your primary optics.

Scope ring mounts

Photo Credit: Reptilia Corp

Red dots can conveniently be mounted directly onto the primary optic. The Trijicon ACOG and RMR combo is a battle-proven duo that's made possible with a mounting plate that sits on top of the ACOG. Odds are that there's a ring clamp mount that will attach to any of the market's favorite optics out there. Sitting above the scope makes for easy transitions.

Consider the GST-9

Have a Glock-style pistol build going on? The GST-9 frame can serve as the perfect base for what you might have in mind. The GST-9 modular grips can be configured to the length for you whether it’s a G17 length grip or a G19 length grip. If you do pick up some GST-9's make sure you get the 5D Tactical Pistol Jig Pro to complete it!